SPONSORED

Most cars still operate like they’re stuck in the mechanical age – pedal pushes brakes, steering wheel turns front wheels, end of story.

IM presented by MG Motor is a new-to-Australia premium auto brand that boasts a cutting-edge digital chassis, tossing that notion out the window in favour of something that sounds like science fiction but drives like automotive reality.

Think of it as your car developing a functioning nervous system, one that can sense and correct trouble before your reflexes even register there’s a problem.

The IM5 sedan and IM6 SUV don’t just bolt computers onto conventional chassis components – they reimagine the entire relationship between hardware and software.

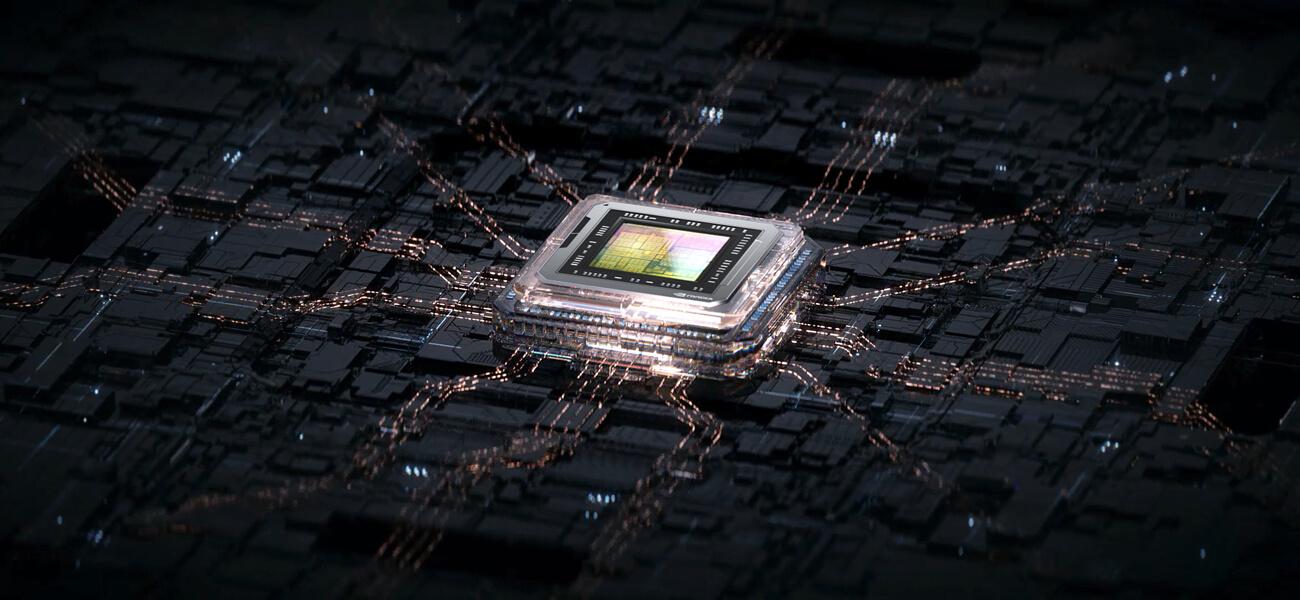

With over 3000 semiconductors coordinating everything from suspension response to brake pressure, these vehicles represent the first genuine step toward cars that think faster than their drivers.

It’s not about replacing human judgment; it’s about giving that judgment superhuman reflexes and near-psychic anticipation of what’s coming next.

What Is a digital chassis?

Traditional chassis engineering follows a straightforward philosophy: mechanical components respond to driver inputs through hydraulic, pneumatic, or electronic systems that operate independently. Your brakes do the braking, your suspension handles bumps, your steering manages direction – each system in its own lane, so to speak.

IM’s digital chassis completely flips this approach. Instead of separate systems responding to individual commands, IM by MG Motor models use a centralised computing platform that orchestrates every dynamic component simultaneously.

Indeed, the IM5 sedan and IM6 SUV’s shared 800V electrical architecture doesn’t just power the car; it enables real-time interaction between suspension, steering, braking, and powertrain systems at speeds that render human reaction times obsolete.

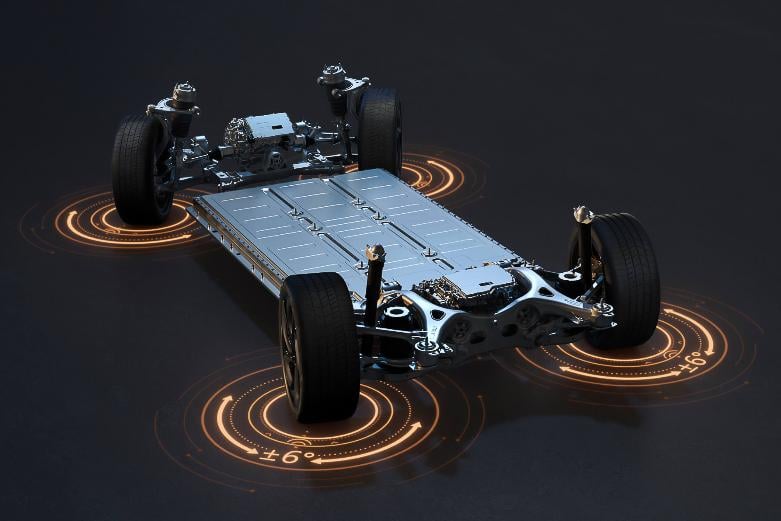

The hardware foundation includes four-wheel independent suspension with adaptive damping, bi-directional rear-wheel steering capable of 12 degrees of articulation, and brake-by-wire systems that can modulate individual wheel pressure in milliseconds.

But the real magic happens in the software layer – algorithms that process data from dozens of sensors, predicting vehicle behaviour and adjusting responses before physics has time to catch up.

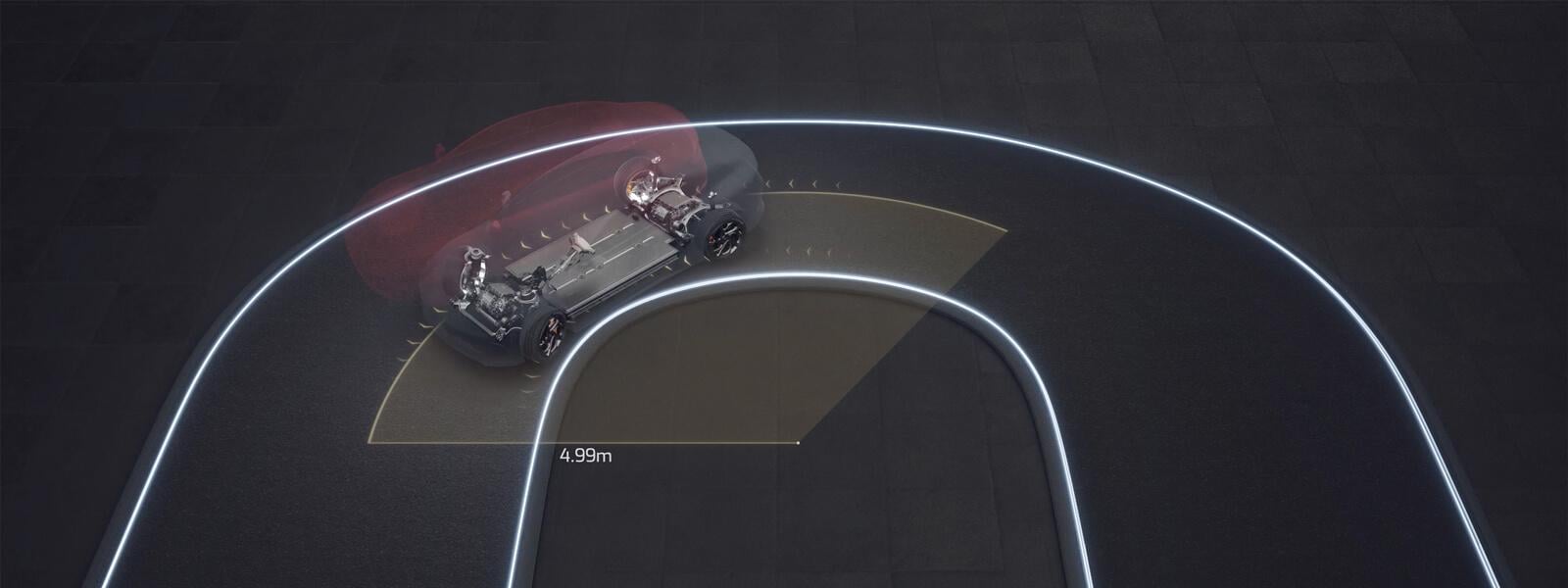

What separates this from existing stability control systems is scope and speed. Where traditional ESC might intervene when you’re already sliding, IM’s digital chassis identifies the conditions that lead to slides and prevents them from developing.

It’s the difference between catching someone who’s already falling and ensuring they never lose their footing in the first place.

How does it work?

Picture the digital chassis as your car’s cerebellum – the part of the brain that coordinates movement without conscious thought.

While you’re focused on navigation and traffic, the system is continuously analysing road surface conditions, vehicle load distribution, weather data, and driving dynamics to predict what’ll happen next.

IM by MG Motor uses an advanced NVIDIA Orin N Chip at its core and integrates real-time machine learning. The process operates in loops measured in milliseconds. Sensors monitor everything from tyre pressure fluctuations to microscopic changes in wheel speed, feeding data to processing units that can execute thousands of calculations per second.

When the system detects the early signs of instability – perhaps a slight weight transfer that suggests impending understeer, or road surface conditions that indicate reduced grip – it doesn’t wait for the driver to respond.

Instead, it orchestrates a coordinated response across multiple systems. The rear wheels may steer slightly to maintain ideal weight distribution, for example.

Suspension damping adjusts to optimise tyre contact patches, and individual brake callipers apply precisely calculated pressure to maintain the intended trajectory. All of this happens transparently, without driver intervention or even awareness.

The bi-directional rear steering system exemplifies this integration. At low speeds, the rear wheels turn in the opposite direction to the front wheels, in effect shortening the wheelbase for parking and other tight manoeuvres. MG calls this crab model.

As speeds increase, they turn in the same direction as the front wheels, to deliver better handling and stability.

However, the digital chassis takes this further, utilising rear steering as a stability tool – subtly adjusting rear wheel angles to maintain optimal vehicle dynamics even when road conditions or driver inputs could compromise handling.

Why does this matter?

The practical benefits of the IM5 and IM6’s digital chassis extend well beyond impressive technical specifications.

For daily Australian driving – navigating Melbourne’s hook turns, managing Sydney’s stop-start traffic, or handling sudden weather changes on regional highways, for example – the digital chassis delivers tangible safety and convenience improvements.

The safety advantages are immediately apparent. Emergency manoeuvres like sudden lane changes or hard braking on slippery roads – situations where split-second responses determine outcomes – benefit from the system’s ability to coordinate multiple vehicle systems faster than human reflexes allow.

Driving comfort also receives a significant boost. The coordinated suspension and steering response translates to less driver fatigue on longer journeys. At the same time, the revolutionary bi-directional rear-wheel steering technology makes urban parking genuinely less stressful.

When a five-metre sedan can navigate tight spaces like a compact hatchback thanks to its 12-degree rear-wheel articulation, car park anxiety becomes a thing of the past.

The One Touch AI Chauffeur function can even remember your last 100 metres of driving through its trace-back feature – perfect for retracing your steps in those confusing multi-level car parks.

Perhaps most importantly, the digital chassis adapts to different driving conditions automatically through the iSMART app integration and onboard intelligence.

You don’t need to cycle through driving modes or adjust settings – the system continuously optimises performance based on real-time conditions. Whether you’re cruising the open road or navigating a crowded Westfield car park, the vehicle adjusts its behaviour to match the situation without input from your smartphone or dashboard.

The technology also future-proofs the driving experience. As autonomous driving capabilities continue to develop, the digital chassis provides the foundation for even more advanced features. Today it’s preventing slides and optimising handling; tomorrow it could be coordinating with traffic management systems or other vehicles for enhanced safety and efficiency.

The bottom line

Think of the IM presented by MG Motor digital chassis as automotive engineering catching up with smartphone-era expectations. Not gadgets, but technology that works in the background to make things simpler – and better.

It’s not about eliminating the driving experience; it’s about enhancing it with capabilities that would be impossible through mechanical systems alone.

Priced from $60,990 drive-away, the IM5 and IM6 deliver this advanced digital chassis technology without the premium price tag you’d expect.

Given its enhanced safety and broader benefits, the digital chassis is less like automotive showmanship and more like a logical evolution toward smarter, more responsive vehicles that are finally accessible to mainstream buyers.

MORE: Explore the MG showroom